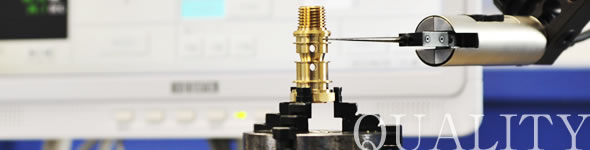

Building a quality assurance system to respond to customer trust.

Matsumoto Kosan's dedication in manufacturing is demonstrated by the establishment of a quality assurance system corresponding to high-precision machining. No matter what how precise our processing is, customer trust cannot be gained without having a testing system for quality assurance. Therefore, we have stepped up efforts in setting up a quality assurance room with an extensive line-up of testing devices.

|

|

| Surface texture and contour integrated measuring instrument | Roundness and cylindrical profile measuring instrument |

Our equipment include the "Surface texture and contour integrated measuring instrument" with 0.005 resolution and 24,000:1 ratio of dynamic range to resolution, the "Roundness and cylindrical profile measuring instrument" capable of measuring roundness, cylindricity as well as coaxiality, flatness and perpendicularity, and "Measuring microscope" for areas that cannot be gauged with a micrometer. We also have the air micrometer that can measure down to 0.1 micron.

|

|

| Measuring microscope | Electric-signal type air micrometer |

In addition, all items go through visual inspection with the human eye for any swarf or scratches, and the introduction of a testing system using computerized image processing is underway to prevent human error.

|

|

| Inspection room | Visual test |